For the garment industry, choosing a high quality and stable interlining is one of the important factors that determine the quality of the garment. Today we will focus on "906 composite interlining " and discuss why it can become the first choice for many brands and tailors.

Understanding 906 composite interlining: definition and characteristic analysis

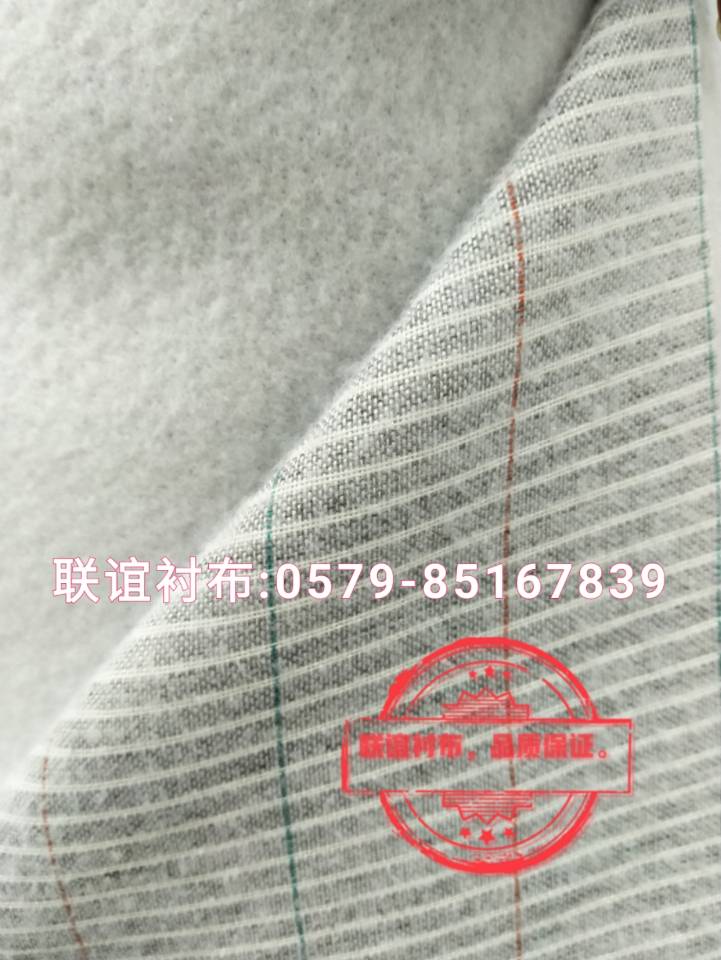

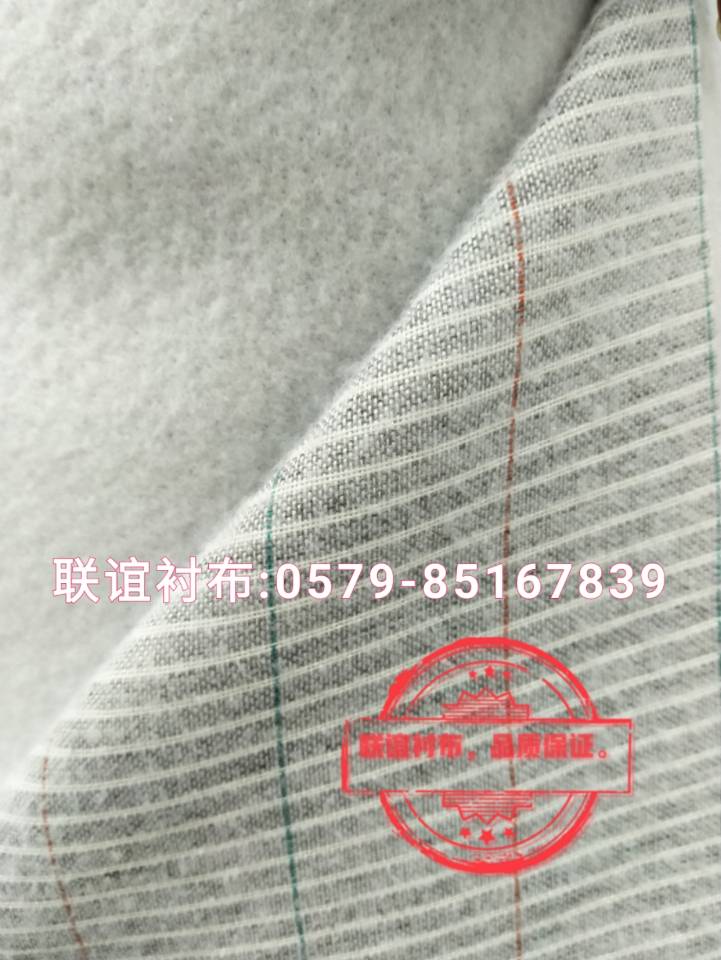

The so-called 906 composite lining cloth is a kind of functional fabric made by special process, which is widely used in the production process of shirts and suits in the field of men's clothing, women's clothing and children's clothing. This type of interlining combines the advantages of cotton fibers and other high-performance materials to ensure flexibility while also providing excellent support.

Why 906 is the ideal companion for shirts and suits

First of all, it needs to be clear that each specific purpose of clothing needs to match the corresponding characteristics of the inner reinforcement components to shape the contour and increase wearing comfort. The 906 series is just such a kind of product line specially designed for the advanced customization market-its thickness is moderate but strong enough to fit the human body curve well and avoid the problem of inconvenience caused by being too thick. Secondly, its excellent anti-wrinkle ability and easy care properties enable the finished product to maintain its original beauty after being washed for many times.

Diversified Inventory Disclosure: Meeting Customization Needs of Various Customers

As consumer aesthetics continue to change and escalate, it is clear that a single standard specification cannot fully cover all potential order sources. Therefore, our 906 composite interlining provides a rich combination of options to choose from, including but not limited to gram weight difference (light and thin VS heavy), color design (pure plain and elegant or with a little texture embellishment) and other aspects of adjustment can achieve the goal of rapid response to customer needs.

Industry Application Case Analysis: Behind-the-scenes Heroes of Successful Brands

Many well-known apparel manufacturers at home and abroad have incorporated them into the core supply chain system for long-term cooperation. For example, an international luxury brand has used this raw material to complete the overall innovation and transformation of its main formal series product line, and has achieved remarkable results-not only greatly improving the satisfaction score of end users, but also effectively reducing the proportion of unit cost expenditure, thus enhancing the level of competitiveness.

How to choose the type and specification of interlining suitable for you

Considering that the actual application scenarios of each buyer are different, the early communication link is particularly important. Under normal circumstances, we will suggest to determine the basic characteristic information of the target audience group first and then formulate the draft document of the preliminary screening plan accordingly. Then through the sample delivery test to verify whether the physical and chemical index data meet the standards before making the final decision.

Maintenance Tips: Key Steps to Extend the Life of the Lining

Although the 906 composite interlining itself has strong durability and excellent performance, if you want it to serve your career for a long time, you need to follow some basic guidelines. For example, it should be stored separately to prevent cross-contamination. Regular cleaning of surface attachments to prevent mold growth and so on are small details that cannot be ignored.