In the pursuit of perfect clothing, every detail is crucial. As a "cornerstone" hidden under the outer layer, high-quality interlining often determines whether the whole garment has sufficient support and advanced texture. Today, we will focus on a highly respected interlining, the 906 composite interlining, and explore why it can stand out from many similar products.

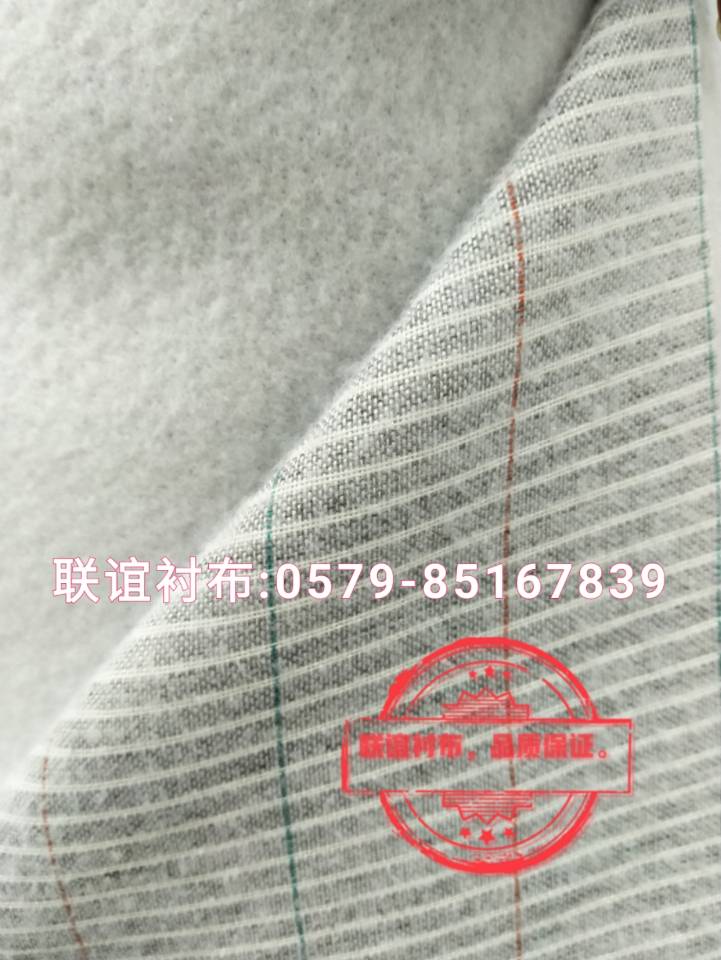

906 composite interlining has won wide recognition in the industry for its excellent performance. Its core lies in the use of advanced composite technology, combining the soft touch of traditional cotton materials with the strong and tough properties of modern technology fibers. This clever fusion allows the finished product to retain the feel of natural materials, while enhancing the overall strength and durability. In addition, through the special coating treatment, good wrinkle resistance and breathability are also achieved, making the wearer more comfortable.

When we delve into the specific types, we find that "chest lining" and "cotton lining" are an integral part of this system. The former is mainly used in the shoulder area of the suit to shape the tall and straight outline; the latter is more common in the collar and cuff position of the shirt to play a reinforcing role. Although the two specifications have different uses, they complement each other to build a complete solution system.

In practice, it is particularly important to choose the appropriate type of lining for different styles of clothing. For example, when customizing a business formal suit style, it is suggested to give priority to using thicker versions such as 906 chest lining to create a strong line aesthetic feeling. However, for casual jackets, a relatively light and thin model may be more suitable to maintain flexibility and mobility without being too rigid and stiff to lose its vitality.

In addition to the outstanding performance of a single product, another advantage that cannot be ignored is the comprehensive inventory support services we provide. Whether the customer needs the regular size standard or special custom needs, here can be met. Thanks to the long-term accumulation of experience and technical strength guarantee plus constantly updated and perfect product line layout planning, to ensure that each order can be delivered to the end user on time and accurately.

The last thing I have to mention is the unexpected benefits of choosing the interlining correctly. It is not just as simple as simply improving the appearance of the image, but more importantly, it can extend the entire life cycle and reduce the overall cost of investment. Imagine if there is such a solid and reliable protective barrier behind every factory work, then it will inevitably give the brand image a greater degree of room for improvement and attract more loyal fans to join it to form a virtuous circle of development.