In the pursuit of perfection, details determine success or failure. For making shirts and suits, choosing the right interlining is essential. Today we will discuss in depth why 906 composite interlining has become the preferred material trusted by many brands.

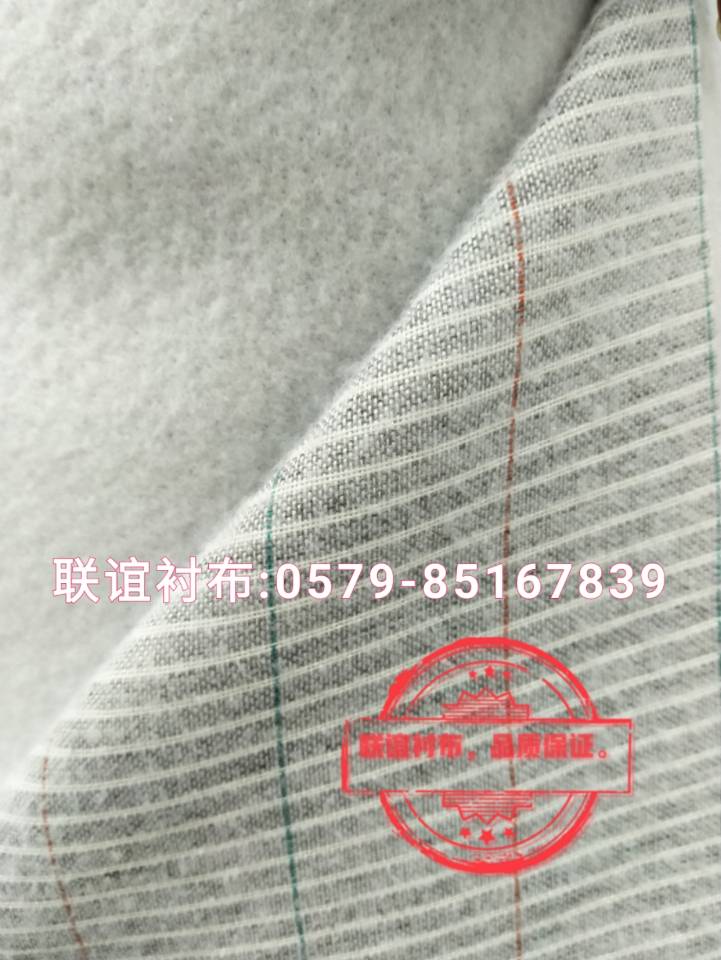

Understanding 906 composite interlining: the core secret of high-end quality

As an industry-leading product, 906 composite interlining has won wide acclaim for its unique performance. It not only has excellent wrinkle resistance and ductility, but also can effectively maintain the overall shape of the clothing, making it as long as new. Thanks to advanced production technology and technical support, this interlining can perform well in different climatic conditions, thus providing consumers with an unparalleled wearing experience.

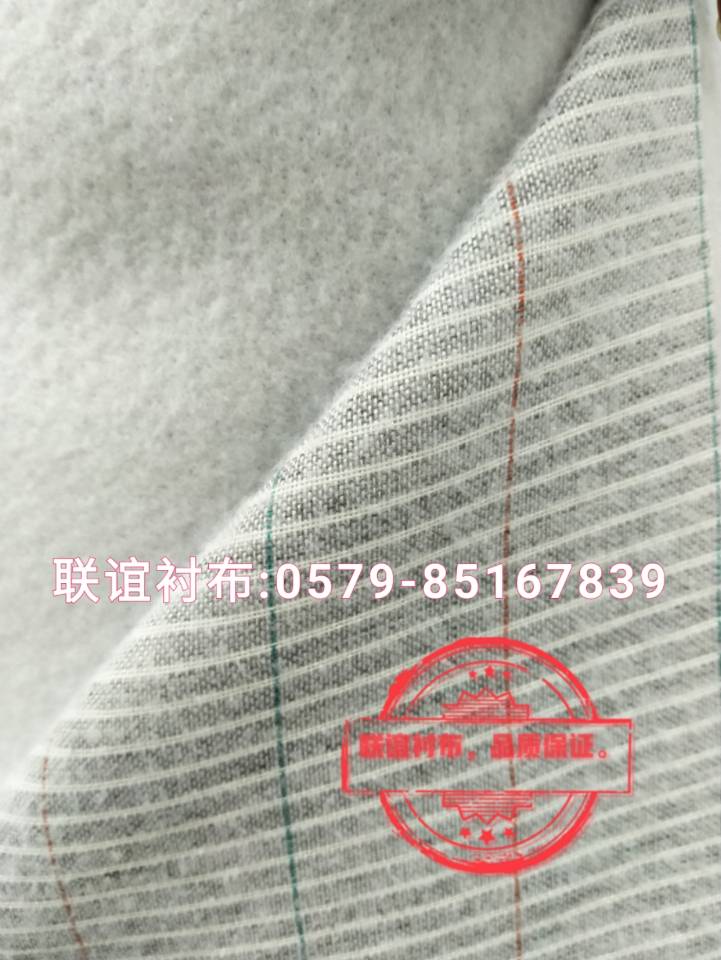

Multi-Purpose Solutions: Diverse Choices for All Types of Clothing Needs

Whether it is a classic business dress or casual style of daily clothing, 906 composite interlining can meet the application requirements of a variety of scenarios. This series of products covers various types from light and thin breathable to thick and warm, and can be flexibly selected according to actual needs. At the same time, the rich specification options also allow designers to achieve more creative possibilities, further enhancing the scope of application of the product.

A New Definition of Comfort: Why Cotton Is Highly Admired

In addition to functionality, comfort is also one of the important criteria for measuring a good interlining. The high quality cotton material used in the 906 composite interlining is the best proof of this. Compared with other synthetic fibers, pure natural cotton has better moisture absorption and perspiration ability and soft touch, even if it is worn for a long time, it will not produce discomfort. More importantly, this environmentally friendly raw material is skin-friendly and easy to take care of, and truly achieves both beauty and practicality.

From cutting to finished product: ensure quality stability at every step

In order to ensure that the final results are consistently excellent, the entire production process is strictly monitored and managed. From the screening of raw materials until the packaging factory, each link has a special person responsible for inspection and testing, to eliminate the possibility of all potential hidden dangers. Such a rigorous attitude also makes every customer can rest assured to buy and use related products without worrying about quality problems.

Worry-Free Purchasing Guide: Adequate inventory gives you peace of mind

Finally, we have to mention that we are committed to providing stable and reliable supply services. With a sound warehousing system and efficient logistics network, even in the face of sudden orders can quickly respond to delivery. This means you can get the resources you need anywhere and anytime without the risk of stock-out-time is money, after all!