When we talk about the perfect suit or shirt, we usually focus on the fabric, cut and style. However, behind these obvious factors, there is a crucial element-that is the choice of lining . Today we will focus on a product favored by the industry:906 composite interlining series .

906 composite interlining has been able to stand out, mainly due to its unique charm. Whether it is high-end customization or mass production, this set of solutions can always meet a variety of complex needs. From the selection of materials to the process, every detail has been carefully polished, and strive to present the most ideal wearing experience.

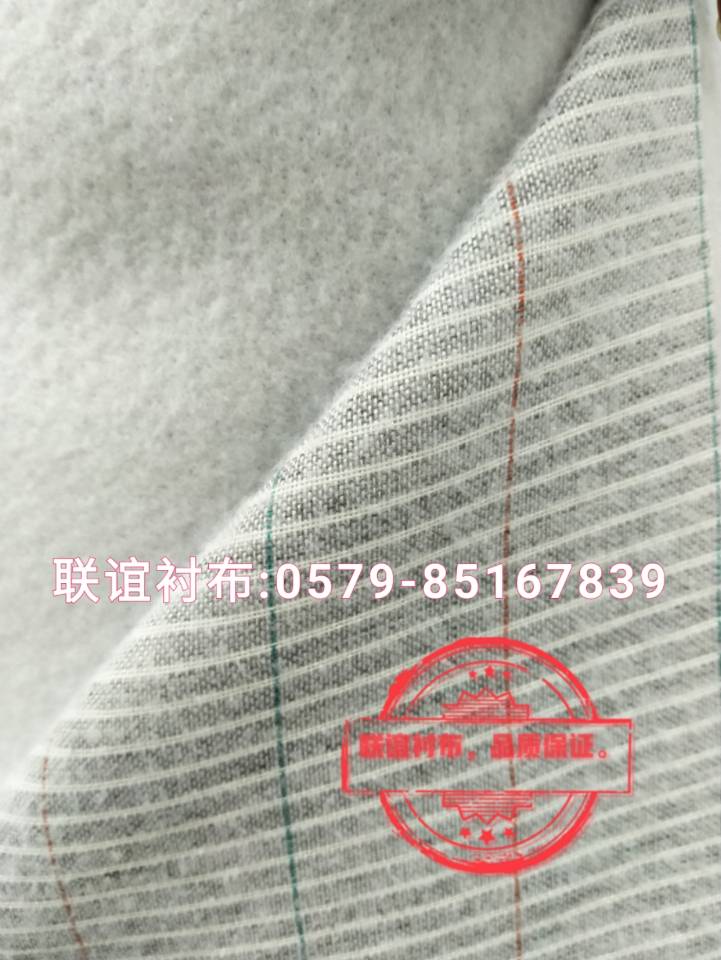

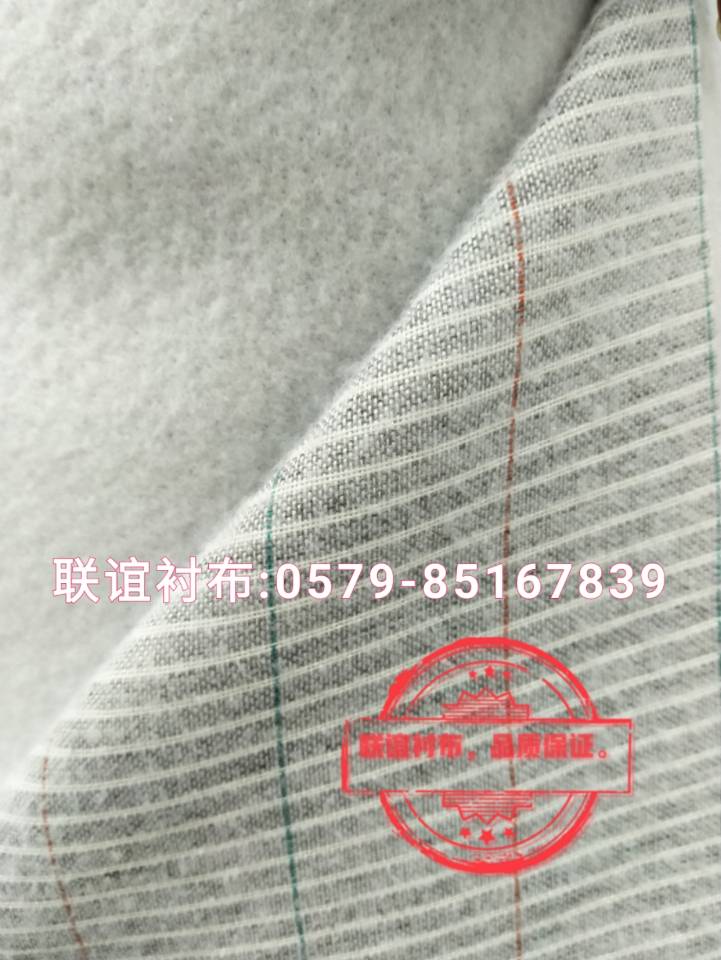

In-depth study of the manufacturing process of 906 composite interlining is not difficult to find that it uses first-class raw materials and is processed with advanced bonding technology. Specifically, this interlining is based on natural fibers, supplemented by a hot-melt mesh film to form a strong sandwich structure, which gives the finished product excellent flexibility and breathability. This feature not only enhances the overall stiffness of the clothing, but also greatly improves the wearing comfort.

It is worth mentioning that for different use scenarios, the "906" family provides a wealth of options for customers to freely combine.

For example, for the pursuit of the ultimate light feel of business suits, you can choose a thin cotton lining; and for the emphasis on the chest line shaping effect of the work uniform, you recommend a special chest pad style, etc. ...... Each configuration scheme has been tested and verified for countless times before it is finally determined to ensure that the ideal balance point is reached.

In recent years, as the society has paid more and more attention to the concept of sustainable development, more and more well-known brands have begun to choose environmentally friendly and reliable suppliers to cooperate. The manufacturers of "906 composite interlining" obviously know this well. While ensuring product quality, they actively promote green production processes to reduce energy consumption and waste emissions, which has won wide recognition and support.

Then the question arises-how can we use these tools to further optimize the quality of our garments?

in fact, the answer is very simple: first, make clear the target market positioning and the expected audience preference; Secondly, according to the functions of different parts, select matching models and apply them.

for example, the neckline part suggests giving priority to product types with good elasticity so as to better fit the neck curve. The back area is more suitable for designs with strong support and not easy deformation...

finally, don't forget that daily safekeeping is also an indispensable part of prolonging the service life ~ try to avoid rubbing hard or contacting stimulating substances such as strong acid and alkali solution during cleaning. During storage, it is better to lay it flat and ventilate it regularly to prevent mildew and other problems.

to sum up, with the help of professional auxiliary resources like "906 composite interlining cloth", we can create more perfect works and give them back to every loyal consumer!