Behind every perfect suit or shirt is supported by an excellent interlining. In this article, we will delve into a highly respected material -906 interlining fabric-and see how it has become a favorite of many garment manufacturers.

Exploring the Soul of Clothing: The Core Value of 906 Composite Lining

In the world of custom clothing, interlining is often regarded as the "invisible hero", which not only gives the clothes a unique shape and sense of crisp, but also can significantly enhance the wearer's comfort experience. The 906 composite interlining is such a combination of functional and aesthetic value of the ideal choice.

its core advantage lies in its strong flexibility and stability, even after repeated washing can always maintain the initial form, thereby extending the overall service life of clothing.

From material selection to process: deciphering the excellent performance of 906 composite interlining

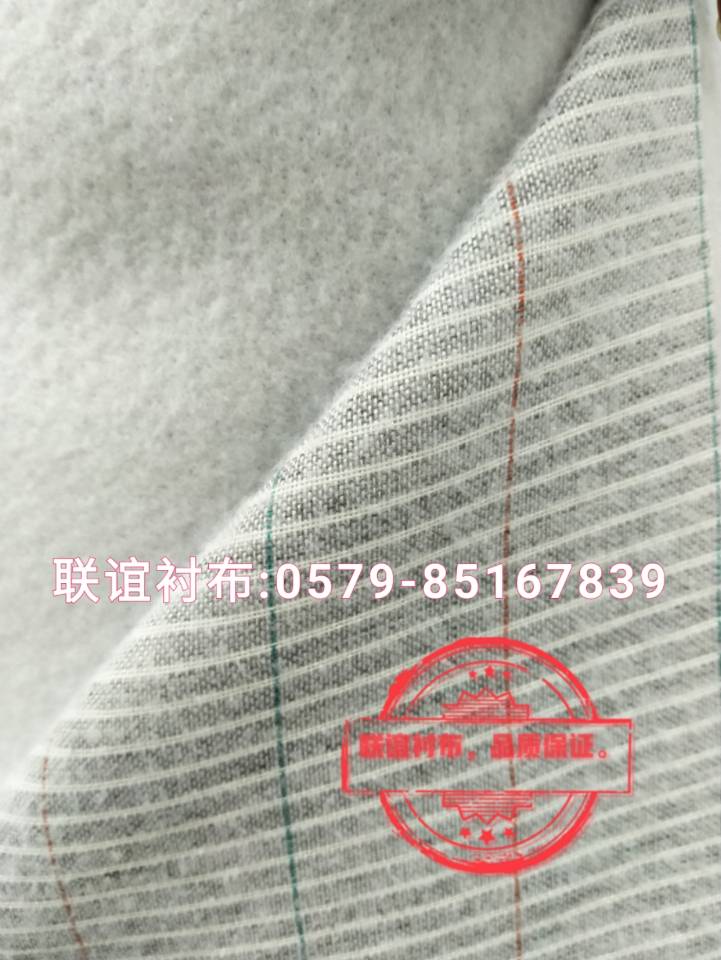

If you want to really know a product, you must go back to its birth process to find the answer. First of all, it is worth mentioning that the lining cloth is woven with high-density pure cotton fiber as the basic raw material, ensuring that the two indicators of air permeability and skin affinity are within the industry-leading level. Secondly, it is fixed with advanced hot melt adhesive bonding technology, which further strengthens the firm connection between layers.

Application Scenario Analysis: Applicable to All-round Players with Various Clothing Types

Thanks to its excellent performance ability and wide range of adaptation, many well-known brands in the market have applied it to their high-end series of works. Whether it is a traditional British-style dress jacket or a simple and modern urban youth's favorite slim short-sleeved T-shirt, it can become more refined and charming with the blessing of this secret weapon.

How to choose the right interlining: practical shopping guide and tips to share

of course, we still need to learn a few simple and effective identification methods before facing a wide variety of options ~ for example, we can test the elastic recovery by gently pulling the edge part or carefully observing whether the surface texture is uniform and delicate to carry out preliminary judgment and screening work. In addition, taking into account the cost budget, it is recommended that as far as possible priority should be given to those who have a complete inventory system and a full range of professional suppliers to provide more reliable goods.

Customer Testimonial: A Real Case Study of the Changes 906 Composite Lining Brings

Last but not least, the feedback from loyal users proves that all efforts have not been in vain. "Since switching to this new model, I obviously feel that the workmanship has improved several grades!" "I used to worry about deformation and shrinkage when I washed too much. Now I don't have to worry about these problems at all." The frequent occurrence of such rave reviews is enough to explain the problem, isn't it? So if you are still hesitant to give it a try, you may as well take action and experience it yourself. I'm sure I won't disappoint you!