Understanding Composite Interlining

The term "composite interlining" refers to a multi-layered fabric that serves as the inner support structure in garments like suits. Its primary purpose is to provide shape, stability, and support to the outer fabric, thereby enhancing the overall fit and appearance.

Historically, interlining materials have evolved significantly, from traditional horsehair fabrics to modern synthetic blends. The advancements in interlining technology have allowed for better performance in terms of durability, comfort, and environmental impact.

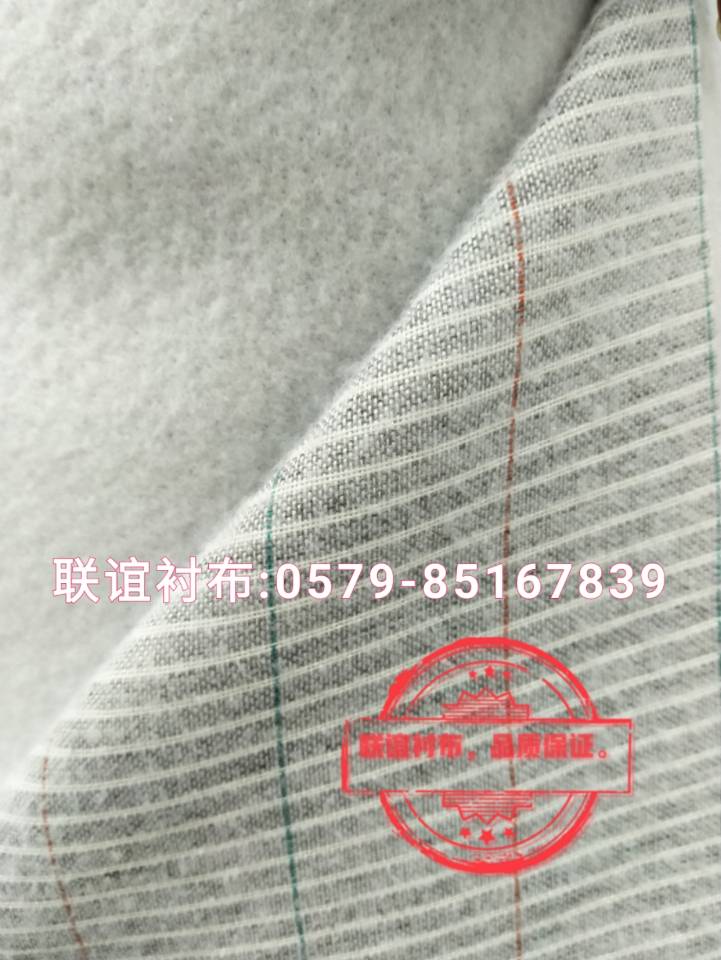

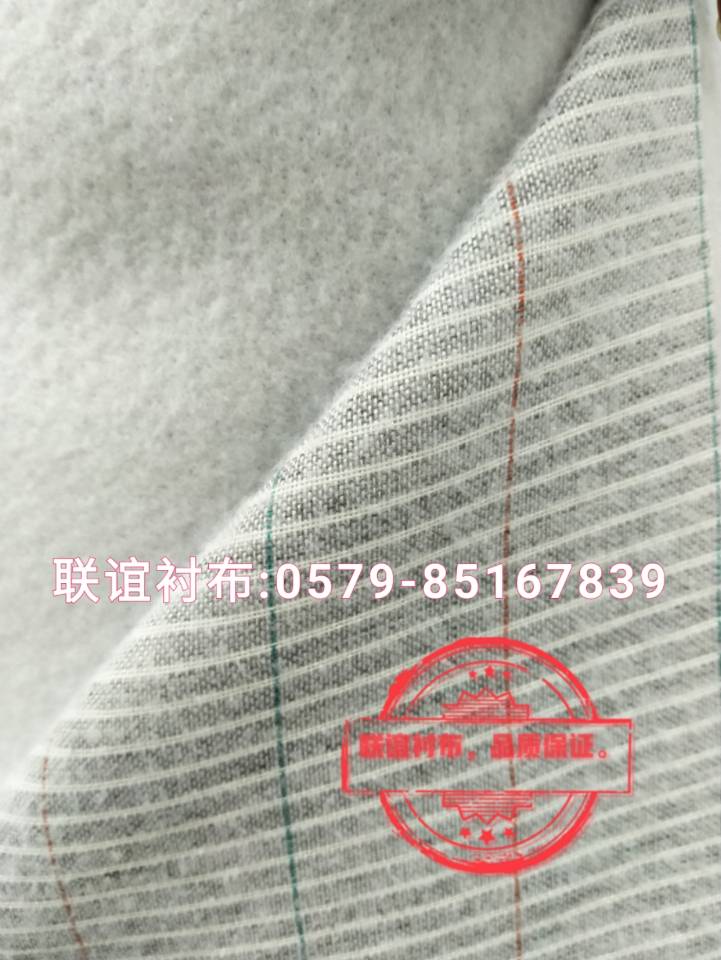

Composite interlining differs from traditional materials by combining various components to achieve superior properties. While traditional interlinings often rely on a single type of fabric, composite interlining integrates multiple layers, each contributing unique benefits.

The Unique Composition of 906 Composite Interlining

The 906 Composite Interlining is a state-of-the-art material designed to meet the highest standards of suit making. It consists of multiple layers, including cotton and non-woven fabrics, each selected for their specific functions. The cotton layer provides breathability and comfort, while the non-woven layers add structure and durability.

Technological innovations have played a significant role in the development of the 906 Composite Interlining. Advanced manufacturing techniques ensure precise layering and bonding of different materials, resulting in a product that offers exceptional performance.

One of the standout features of the 906 Composite Interlining is its eco-friendliness. The materials used are sourced sustainably, and the production process minimizes waste and energy consumption. This makes it an excellent choice for environmentally conscious consumers.

Benefits of 906 Composite Interlining for Suits

One of the most significant benefits of using 906 Composite Interlining is its enhanced durability and longevity. The multi-layered construction ensures that suits maintain their shape and appearance over time, even with frequent wear.

The improved structural integrity provided by the 906 Composite Interlining ensures that suits look sharp and well-fitted. The interlining supports the outer fabric, preventing sagging and maintaining the suit's silhouette.

Comfort and flexibility are crucial factors in suit design, and the 906 Composite Interlining excels in these areas. The combination of cotton and non-woven fabrics creates a material that is both breathable and flexible, allowing for ease of movement and all-day comfort.

Additionally, the 906 Composite Interlining offers excellent resistance to wear and tear. The robust construction ensures that the suit withstands the rigors of daily use, making it a reliable choice for business and formal occasions.

Tailoring Advantages

For tailors, the 906 Composite Interlining offers several significant advantages. Its ease of application reduces the time and effort required to construct a suit, leading to increased efficiency and productivity.

The versatility of the 906 Composite Interlining makes it compatible with various fabrics, allowing tailors to create suits from a wide range of materials. This adaptability ensures that the interlining can be used in numerous design styles and preferences.

Achieving a precision fit is essential for a high-quality suit, and the 906 Composite Interlining facilitates this. Its supportive structure helps tailors create a perfect silhouette, ensuring that the suit fits the wearer impeccably.

Designer Insights

Renowned fashion designers have praised the 906 Composite Interlining for its exceptional qualities. Testimonials highlight its role in creating suits that not only look great but also perform well over time.

Case studies from top fashion houses reveal the success of integrating the 906 Composite Interlining into their suit designs. These real-world applications demonstrate the material's effectiveness in achieving both aesthetic and functional goals.

When compared to other popular interlining choices, the 906 Composite Interlining stands out for its combination of durability, comfort, and sustainability. Designers appreciate its ability to enhance their creations without compromising on quality.

Consumer Experience

End-users have expressed high levels of satisfaction with suits featuring the 906 Composite Interlining. Testimonials often mention the comfort, fit, and longevity of these suits, reinforcing the material's reputation for excellence.

Long-term wear tests have further validated the 906 Composite Interlining's performance. Suits maintain their shape and appearance over extended periods, proving the material's durability and reliability.

To ensure the longevity of suits with 906 Composite Interlining, proper care and maintenance are essential. Regular cleaning, careful storage, and following the manufacturer's guidelines will help preserve the suit's quality.

Market Trends and Future Prospects

The popularity of the 906 Composite Interlining is on the rise, with increasing demand from both tailors and consumers. This trend reflects a growing appreciation for high-quality, durable, and eco-friendly interlining materials.

Innovations in interlining technology continue to emerge, promising even better performance and sustainability in the future. The 906 Composite Interlining is at the forefront of these advancements, leading the way in suit-making materials.

As the market for high-quality suits expands, the future prospects for the 906 Composite Interlining are promising. Predictions indicate that it will remain a preferred choice for both designers and consumers seeking the best in suit interlining technology.

How to Source 906 Composite Interlining

Sourcing high-quality 906 Composite Interlining is crucial for achieving the best results in suit making. Trusted suppliers and manufacturers, such as Zhejiang Lianyi Non-Woven Fabrics Co., Ltd, offer a complete variety of this interlining in stock.

Pricing and availability can vary, so it is advisable to research and compare options to find the best deals. Ensure that you select authentic 906 Composite products by verifying the supplier's reputation and product specifications.

For those interested in DIY suit projects, purchasing from reputable sources will provide the assurance of quality and performance. This is essential for achieving professional results in your tailoring endeavors.

DIY Suit Projects Using 906 Composite Interlining

Home tailors can benefit greatly from using the 906 Composite Interlining in their suit projects. A step-by-step guide can help you apply this material effectively, ensuring a professional finish.

Essential tools and materials for DIY projects include sharp scissors, a sewing machine, and quality threads. Having these on hand will make the process smoother and more efficient.

Common mistakes to avoid include improper cutting and incorrect layering. Taking the time to precisely measure and align the interlining will result in a better-fitting suit.

Conclusion

In summary, the 906 Composite Interlining offers numerous benefits for suit making, from enhanced durability and comfort to environmental sustainability. Its unique composition and advanced manufacturing techniques make it a superior choice for both professional tailors and DIY enthusiasts.

Investing in high-quality interlining is crucial for creating suits that not only look great but also stand the test of time. The 906 Composite Interlining is a testament to the advancements in interlining technology and its impact on modern fashion.

We encourage you to try the 906 Composite Interlining for your next suit project and experience the difference it can make. With its exceptional qualities, it is the perfect choice for achieving the best results in suit making.