Why Choose 906 Composite Interlining for Your Suits?

The Importance of Interlining in Suit Construction

Interlining is a crucial component in suit-making, providing the essential support and structure that defines a well-crafted suit. Historically, interlining materials have evolved from horsehair and cotton to more advanced synthetic blends. The role of interlining extends beyond mere support; it significantly impacts the overall structure and feel of a suit, ensuring it maintains its shape and drapes elegantly.

Key Benefits of 906 Composite Interlining

Robust Durability

The 906 Composite Interlining stands out for its exceptional durability. It is designed to resist wear and tear, offering longevity that surpasses traditional interlining materials. This means suits constructed with 906 Composite Interlining can withstand frequent use while maintaining their structural integrity.

Enhanced Comfort

Comfort is paramount in any suit, and the 906 Composite Interlining excels in this area. Its breathability and moisture-wicking properties ensure that the wearer remains comfortable in various climates. Additionally, its lightweight yet supportive structure allows for ease of movement without compromising on the suit's form.

Technical Advantages

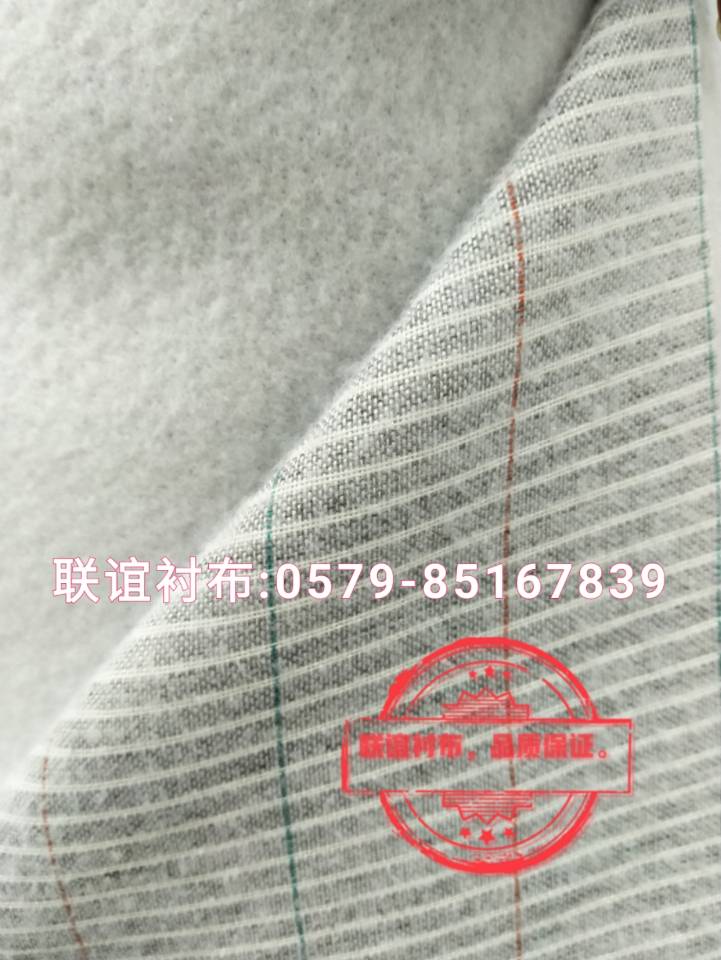

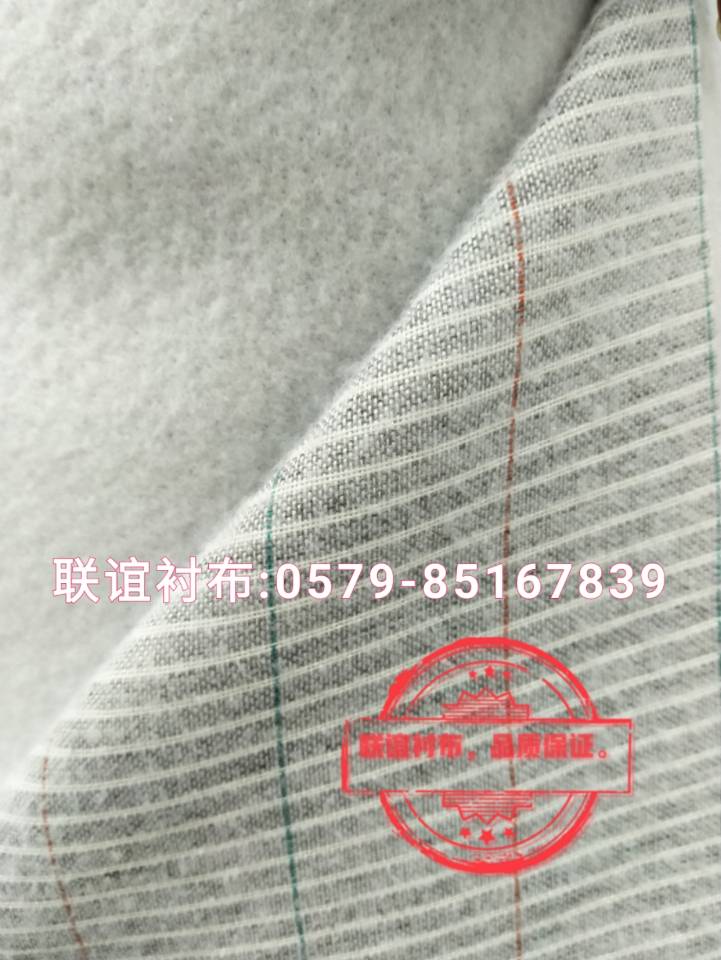

Innovative Material Composition

The 906 Composite Interlining is crafted from a unique blend of fibers that provide superior performance compared to standard interlining materials. This innovative composition ensures a balance of strength, flexibility, and comfort, setting it apart in the market.

Precision in Manufacturing

Advanced production techniques are employed in the creation of the 906 Composite Interlining, ensuring consistency in quality and performance. This precision manufacturing guarantees that each piece meets the highest standards, providing reliable results for tailors and designers.

Aesthetics and Fit

Improved Suit Silhouette

One of the standout features of the 906 Composite Interlining is its ability to maintain the shape of the suit. This is particularly beneficial for tailoring and custom fits, as it helps create a sharp, professional silhouette that enhances the overall appearance of the suit.

Smooth Finish and Feel

With the 906 Composite Interlining, fabric puckering is significantly reduced, resulting in a smooth finish and enhanced drape. This ensures that the suit not only looks impeccable but also moves gracefully with the wearer.

Cost-Effectiveness

Longevity vs. Initial Investment

While the initial investment in 906 Composite Interlining may be higher than traditional options, the longevity it offers results in a lower total cost of ownership. The durability and reduced need for alterations or replacements translate into long-term savings.

Value for Professional Tailors

For professional tailors, the efficiency in suit production and the high level of client satisfaction provided by the 906 Composite Interlining are invaluable. Its reliability ensures repeat business and a strong reputation for quality craftsmanship.

Suitability for Various Suit Types

Versatility in Use

The 906 Composite Interlining is highly versatile, compatible with a wide range of suit fabrics and adaptable for both casual and formal suits. This makes it a go-to choice for diverse suit-making needs.

Case Studies and Examples

Fashion professionals have praised the 906 Composite Interlining for its performance. High-end fashion houses have successfully incorporated it into their designs, resulting in superior products that stand out in the market.

Environmental and Ethical Considerations

Sustainability in Material Sourcing

Environmental sustainability is a key factor in the production of the 906 Composite Interlining. The materials are sourced responsibly, and the production processes are eco-friendly, minimizing the environmental impact.

Ethical Manufacturing Practices

Fair labor practices are upheld in the production of the 906 Composite Interlining, ensuring ethical standards are met. This commitment to corporate responsibility and transparency reflects positively on the brand and its products.

How to Choose the Right Interlining for Your Needs

Factors to Consider

When selecting interlining for your suits, consider the purpose of the suit and its usage frequency. Take into account client preferences and specific requirements to ensure the best choice.

Expert Tips

Seasoned tailors and designers recommend prioritizing quality and consistency in interlining materials. Practical insights include testing samples and verifying product specifications to maximize the benefits of the interlining.

Where to Source 906 Composite Interlining

Trusted Suppliers and Manufacturers

Reliable suppliers such as Zhejiang Lianyi Non-Woven Fabrics Co., Ltd. provide high-quality 906 Composite Interlining. Ensure you verify the product's authenticity and explore recommended brands and distributors.

Purchasing Tips

Consider the advantages of bulk buying to reduce costs. Ensure quality control upon delivery by checking the product against specifications and conducting thorough inspections.

Final Thoughts

The 906 Composite Interlining offers numerous advantages, from durability and comfort to technical superiority and cost-effectiveness. Prioritizing quality in suit-making will lead to better results and satisfied clients. As the industry continues to innovate, exploring advanced materials like the 906 Composite Interlining will keep you ahead in the world of fashion.